Electrical Enclosures: What is NEMA 6 and NEMA 6P?

Type 6 and 6P Definition with General Reference Applications

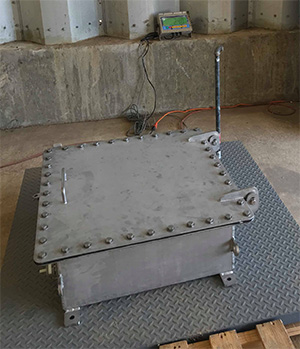

Submersible NEMA 6 and 6P electrical enclosures made from premium carbon and stainless steel box. They are used to protect electronic controls for a power plant or any offshore facility. We also use Submersible NEMA 6P to protect security systems for any applications that put in an indoor/outdoor environment. They give the equipment protection against foreign substances such as dust, and water.

Enclosures Key Features:

- Industry Standard 6, 6P (IP67, IP68) Rated Enclosures

- Performance Rated Enclosures to 150 FT Submersion

- UL Compliance & Performance Testing services are available

- Type 6/6P Enclosures Sizes from 4″x4″x4″ to 72″x48″x24″

- Custom Electrical Conduit Hubs & Pipe Flanges available

- Heavy Duty, Corrosion Resistant Stainless Steel (grades 304 & 316)

- Powder coated, Light Weight & Strong Aluminum Alloys (5052, etc)

- Tough Marine Epoxy Coatings available for specialty applications

NEMA 6 & 6P Sample Applications

A usual example of NEMA submersible 6P electrical enclosure is made from

stainless steel box and it is used to protect electronic controls for a power plant or offshore facility. In addition to this, the submersible type 6P is used for security systems that are used indoors or outdoors depending on the application. Security systems need more protection from water ingress. NEMA grade 6P enclosures are more expensive because it is made from stainless steel and the cost that it would take to manufacture it is high – including the skill of the craftsman in making this enclosure.

Common Materials For type 6 enclosure

Carbon Steel

Carbon steel compared to other raw material steels has a higher carbon content, including iron and manganese. Carbon steel as an electrical enclosure material is considered to be one of the widely and known used material steel because compared to other steels available, it has many functions and advantages that includes in its efficiency. Carbon steel is malleable, therefore it can be melted and can be turned into different specific shapes.

There are generally four types of carbon steel according to these categories: low or mild steel, medium steel, high steel, and ultra high steel.

Low steel

It contains lower content of carbon among all other types of carbon steel. This type of carbon steel is easier to form a shape and this is the most affordable compared to other types of metals. It is commonly used in manufacturing equipment for construction purposes. Despite the advantages, it has low strength and durability because of the lower carbon content.

Medium steel

Another type of carbon steel which is resistant to longer use or wear and tear. Compared to low steel, this is more durable and stronger. Medium steel is commonly used in producing large metal structures and automotive accessories such as axles, shafts, couplings and other materials applicable to this industry.

High steel

One of the strongest carbon steel ever known because it has a high steel variety. It is generally used in producing high strength springs and wires.

Ultra high steel

A carbon steel type which is very formal but strongly recommended to use in manufacturing knives and axles. These types of carbon steel, metals are used in the production of various types of industrial tools and machines. Ultra high steel carbons are used extensively in producing different cutting tools, drill bits, and knives because these types of tools require strong but very flexible material.